Fusible backings are suitable for all fabrics that can not be framed without distortion and can also secure the embroidery permanently after the embroidery process. You can choose between tear-away and cut-away backing versions. At the moment we offer three fusible backings in different qualities and strengths. Before framing, the adhesive coating is activated by heat pressing or ironing and can thus stabilise the fabric before, during and after framing.

... complicated fabrics

The versatile all-rounder

Premium cut-away backing, fusible 70 g - Weblon+

- for medium to heavy, elastic/stretchy fabrics, coarse knitwear, piqué and functional fabrics

- "invisible" polyamide backing for materials that cannot be clamped or embroidered without puckering or bumps

- Iron-on up to 150 °C - max. 200 °C

- the only soft and thinly coated backing on the market

- for temporary or long-term affixation

- for production of very soft badges on base materials like appliqué fabrics

... light & elastic materials

Easy to remove

Premium fusible tear-away backing, 48 g - CMX

- for light and elastic woven goods; light business shirts, blouses & textiles made of silk or acetate

- available in rolls

- especially suitable for materials that cannot be clamped or embroidered without puckering

- can be ironed on at 130 °C

- removable thanks to its low adhesive properties

- can be stabilised completely or partially using a second backing

... badges

Soft and stable

Fusible tear-away backing, 70 g - SMX

- for medium-weight and elastic woven goods; functional workwear & emblems

- available in rolls

- especially suitable for materials that cannot be clamped or embroidered without puckering

- iron-on from 150 °C to max. 200 °C

- thick backing for serial production of very stable patches that can be sewn on afterwards.

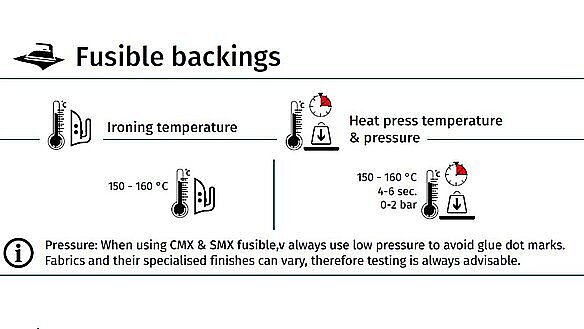

Always work with light pressure so that no adhesive residue remains on the material after tearing off fusible backings.

The fabric and textile properties influence the adhesive performance of fusible backings. For this reason, we always recommend performing tests before starting production.

Changing the temperature, pressure, time and steam can be used to control the adhesive results.

The care instructions of the base material must always be observed!